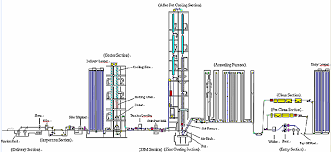

Continuous Galvanizing Line (CGL)

The purpose of the continuous galvanizing line (CGL) is to apply a coating of zinc or zinc/aluminium onto the surface of steel strip to improve corrosion resistance. Galvannealing is optionally performed to alloy the coating into the steel substrate. Very thin formable zinc coatings, ideally suited for deep drawing or painting, can be produced as coated steel products by electrogalvanizing. Zinc is electrolytically deposited on steel products such as sheet, wire, and pipe. The coating is thin and uniform and has excellent adherence. It is free of the zinc crystals present on hot-dip galvanize. The coatings are composed of pure zinc and have a homogeneous structure. (It is also possible to produce electrogalvanize coatings of zinc-nickel and zinc-iron). Electrogalvanize coatings are generally not as thick as those produced by hot-dip galvanizing although some product is made with heavier coating weights. One advantage of electrogalvanizing is that it is done cold and does not alter the mechanical properties of the steel.