Double Cold Reduction Process

First up is thickness reduction in one stand, followed by skin-passing in the second stand. This ensures precise material properties and surface roughness of the tinplate and guarantees smooth further processing. Double cold reduction process for Temper Mill. Upgrade existing 2-stand Temper Mill to Double Cold Reduction Mill

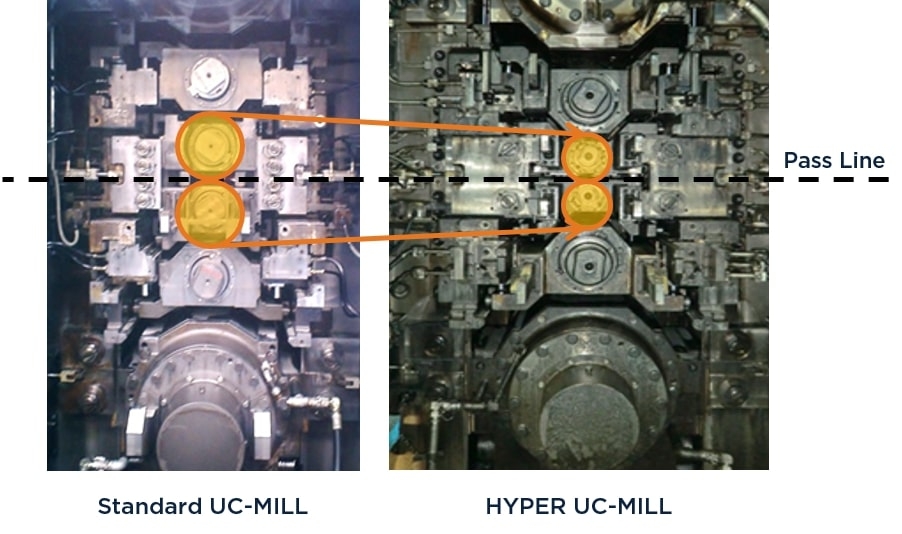

Enables production of even harder and thinner tin plate.

Mill entry and delivery guides can be supplied for direct application or for recirculation coolant system, in both wet and dry tempering modes. Extended product portfolio.

- Categories: CRM Mill Project with Equipments ,